Composite Bags

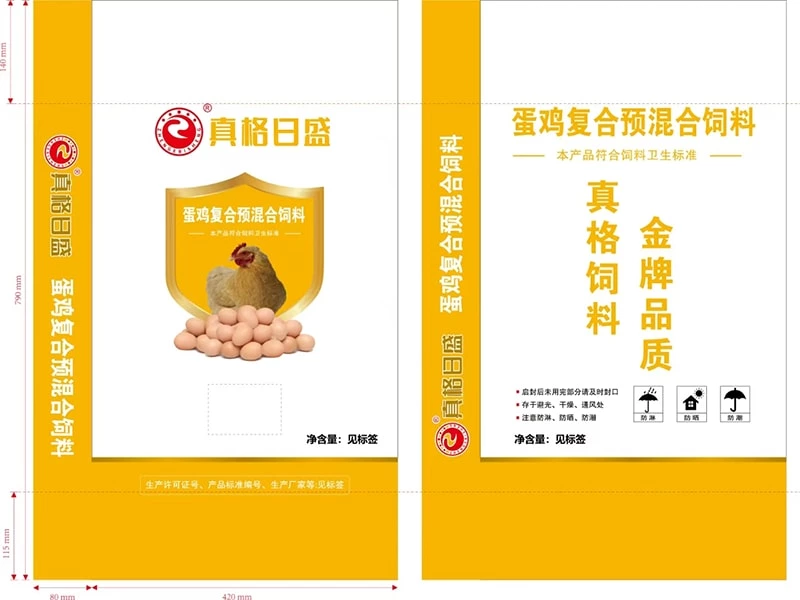

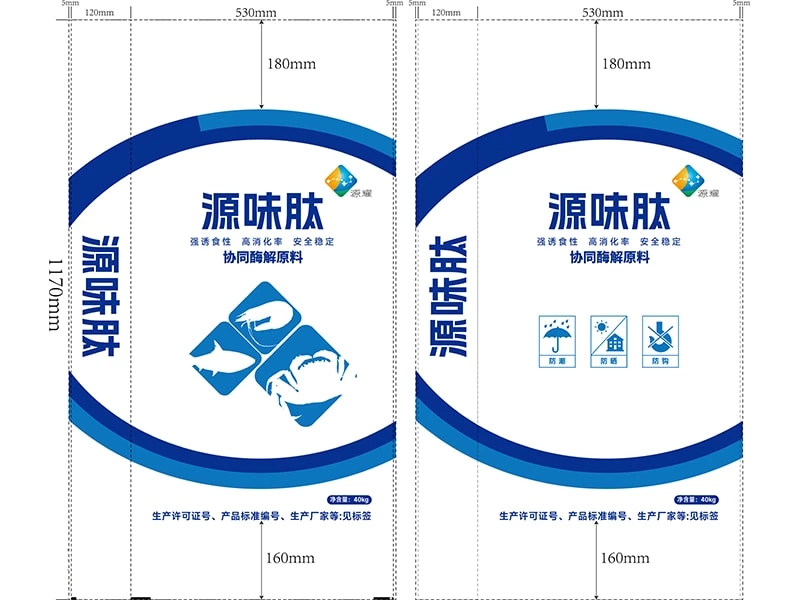

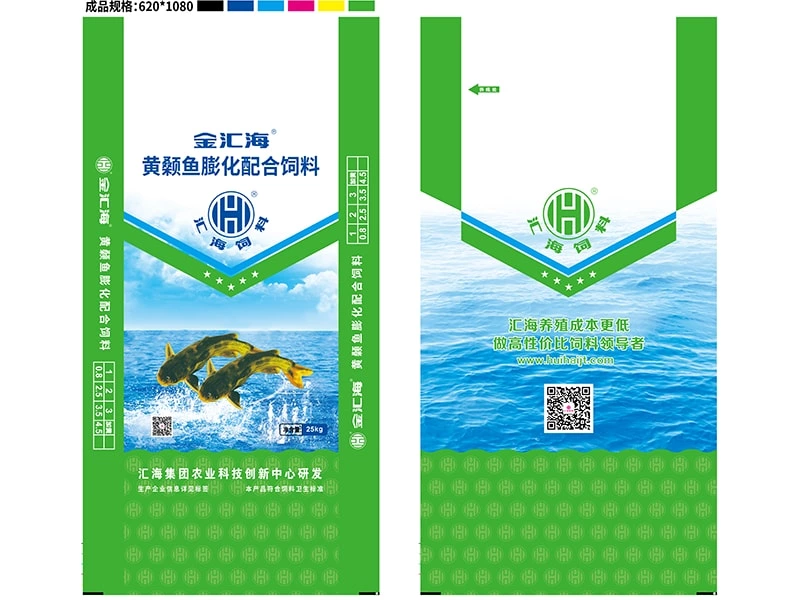

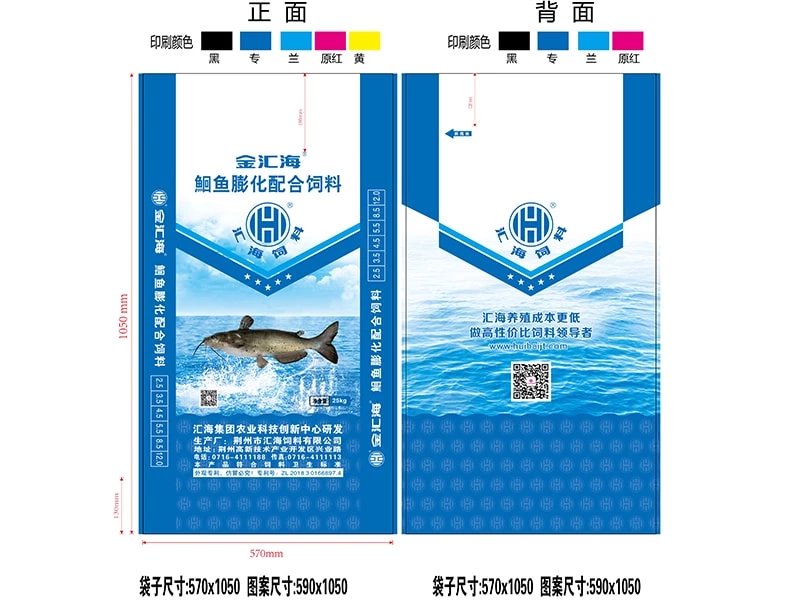

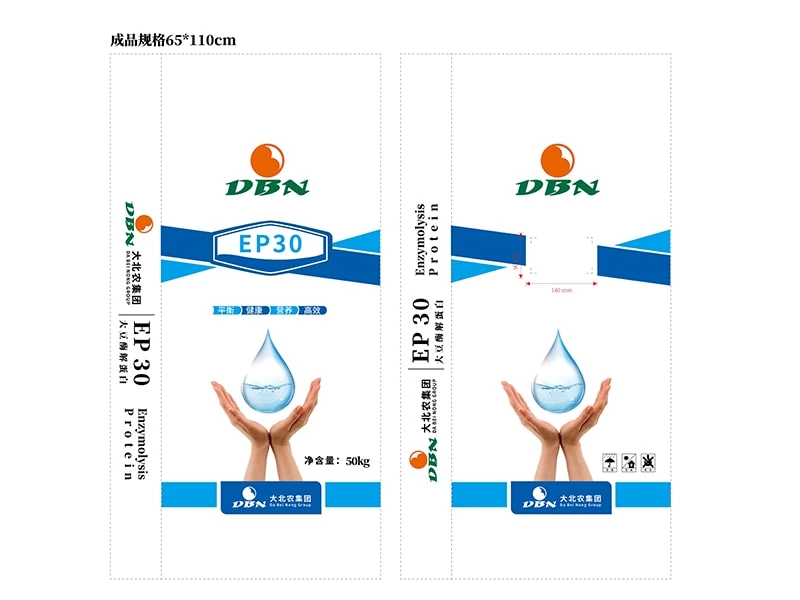

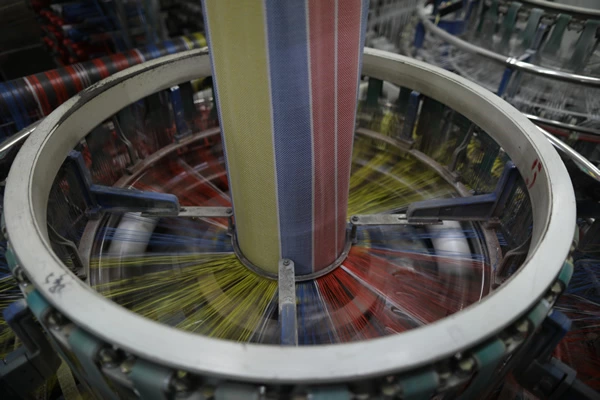

Our composite bags are high-performance packaging materials with a multi-layer structure, made of polyethylene, polypropylene or other composite materials. This type of packaging bag combines the advantages of multiple materials, achieving a unity of high strength, excellent protection, high barrier properties and high-end appearance. It is widely applied in industries such as chemical engineering, building materials, food additives, feed, and minerals, which have strict requirements for packaging. It is suitable for scenarios that require wear resistance and moisture resistance

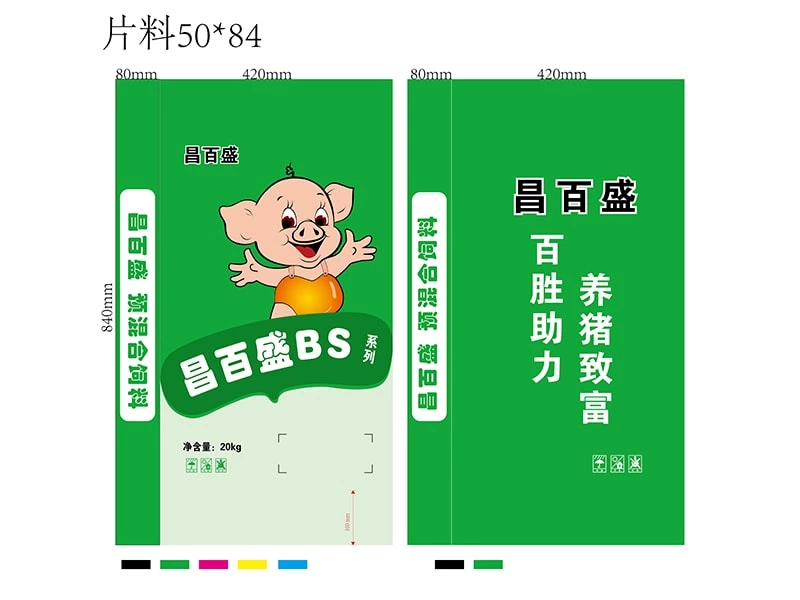

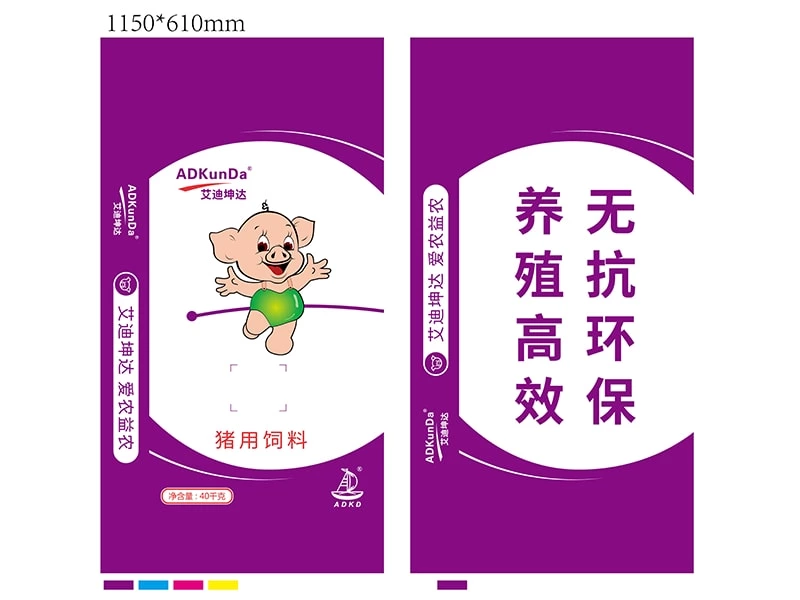

We recognize the importance of both functionality and customization. That’s why our composite bags come with options for reinforced stitching, customized sizes, high-quality printing, and additional features like liners or coatings to meet the specific needs of your product and brand. Whether for agricultural products, industrial materials, or specialty goods, our composite bags deliver optimal performance and visual appeal.

Qiang Li

Purchasing Manager