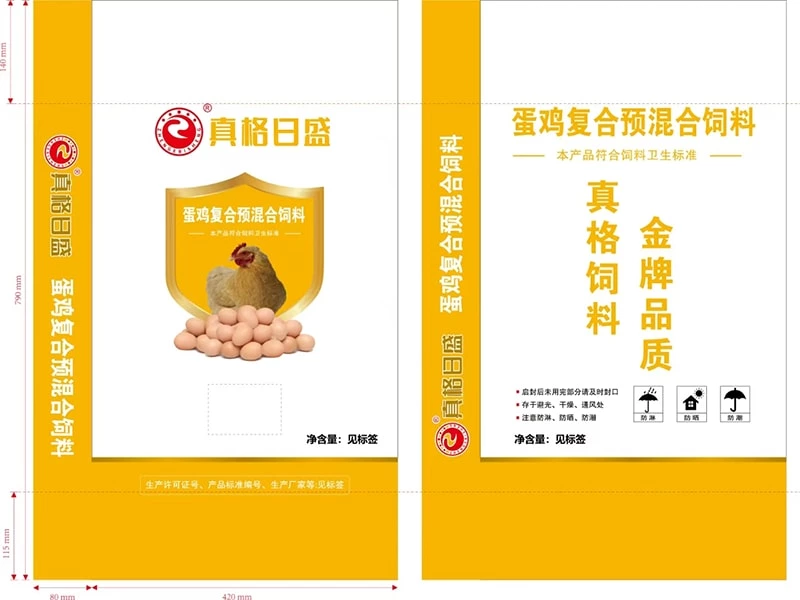

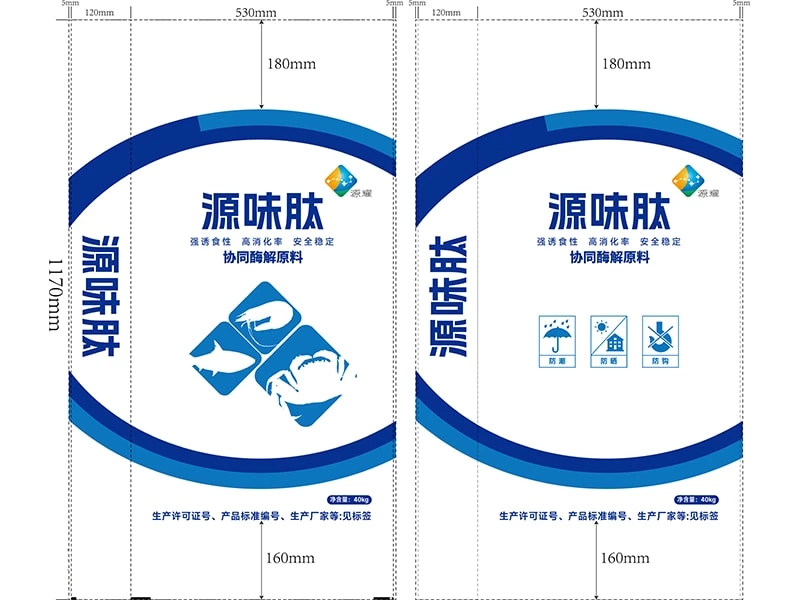

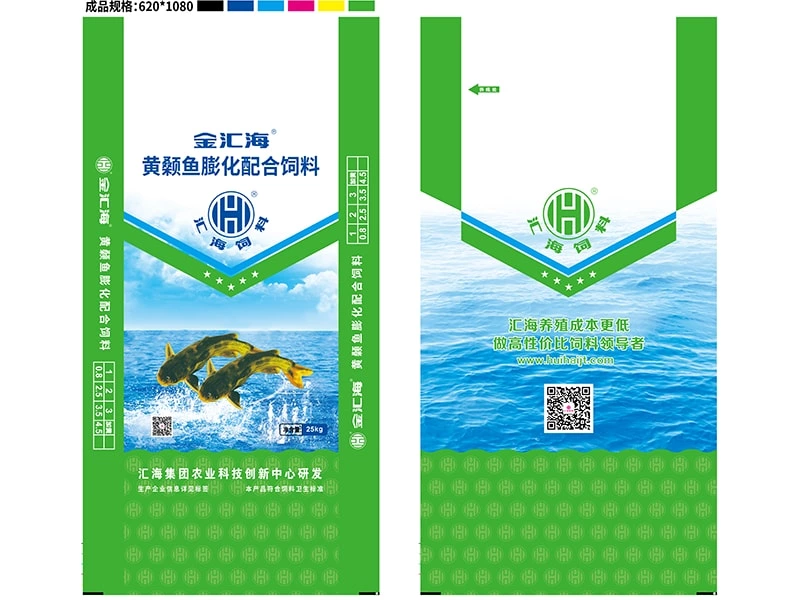

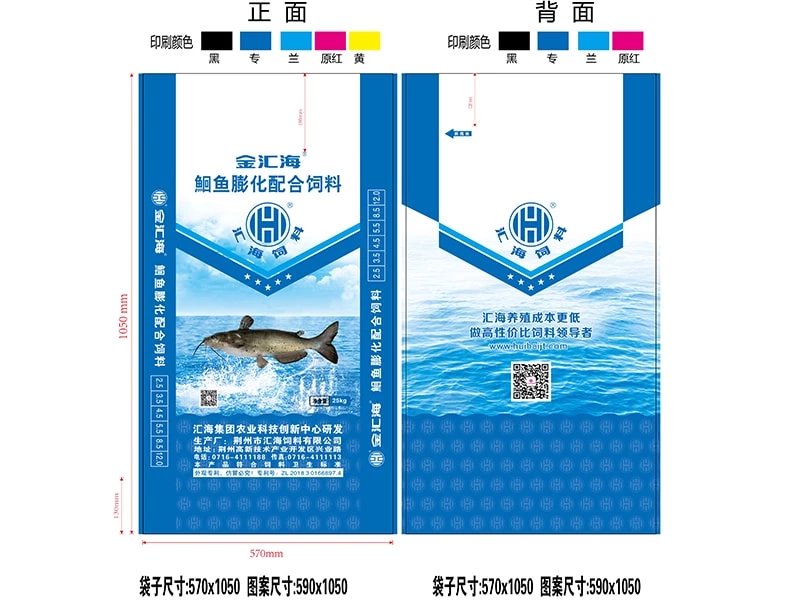

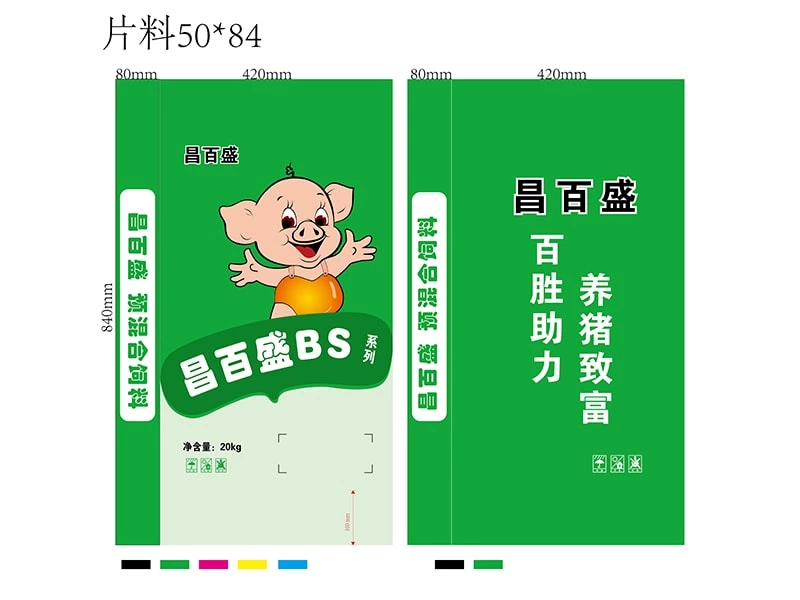

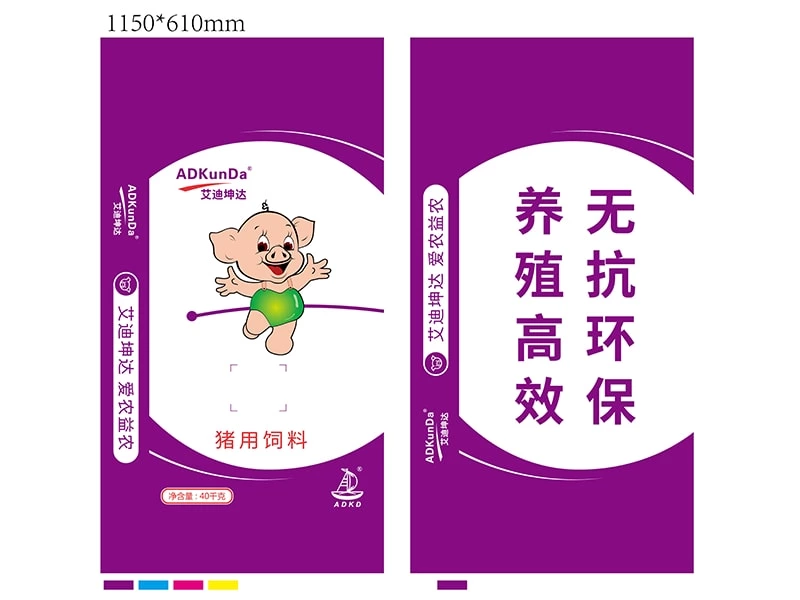

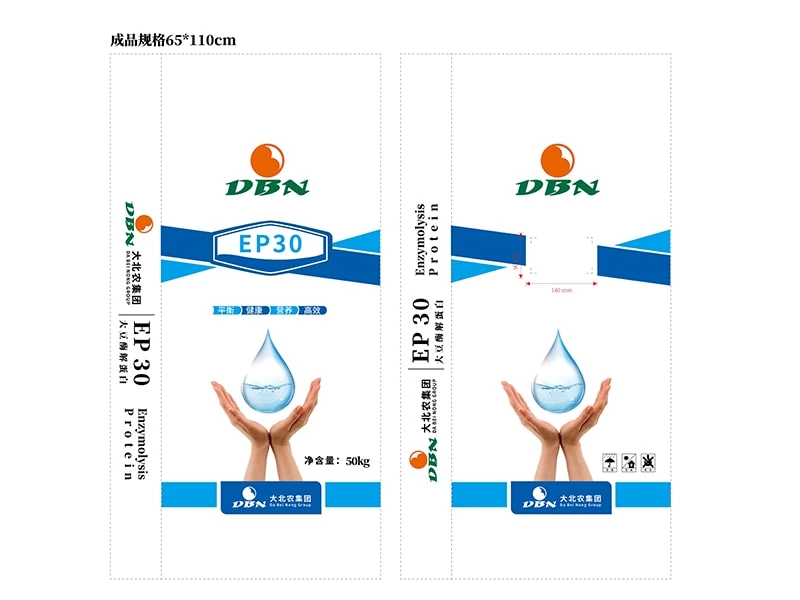

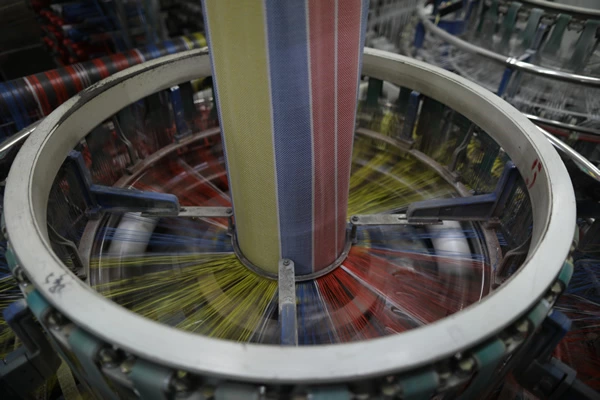

General Packaging Bags

As a professional manufacturer of PP, PE, and composite material packaging, we also offer a wide range of customized solutions beyond food, fertilizer, and industrial use. These include reliable options for pharmaceuticals, daily chemicals, seeds, clothing, logistics, and garden supplies.

Our packaging bags can be tailored in size, material, printing, and closure types such as zippers or handles. With options like stand-up pouches, gusseted bags, and woven sacks, we deliver durable and practical packaging that enhances brand value and adapts to diverse needs.

Qiang Li

Purchasing Manager