Polyethylene Bags

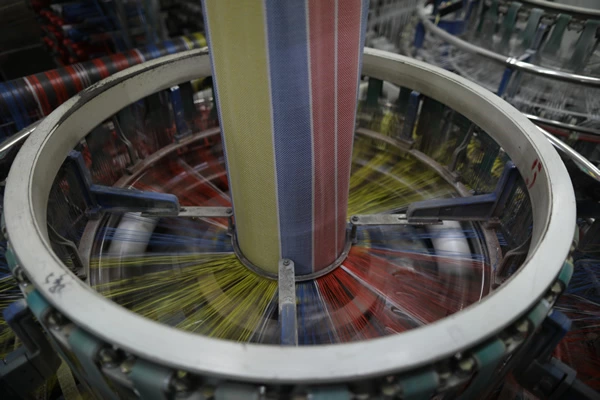

Polyethylene bags widely used across food service, retail, industrial, and agricultural sectors. They offer exceptional moisture resistance, chemical stability, and tear strength.

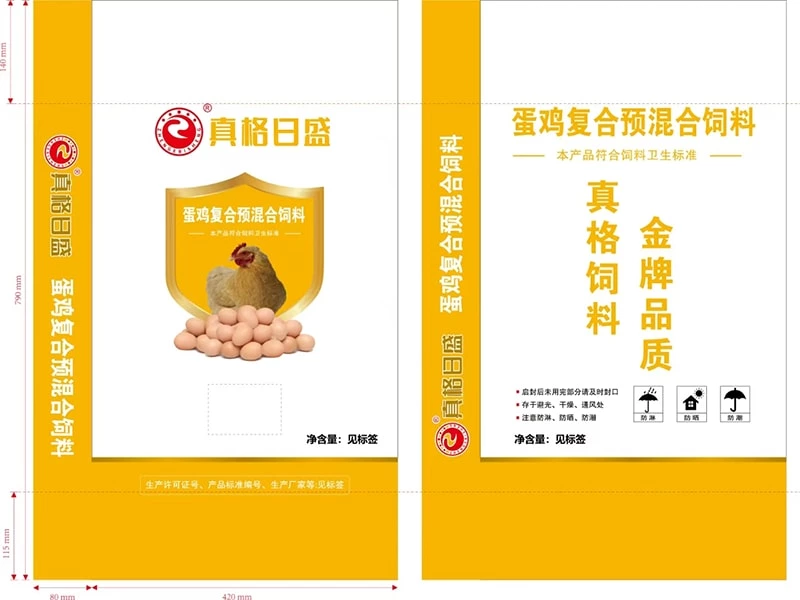

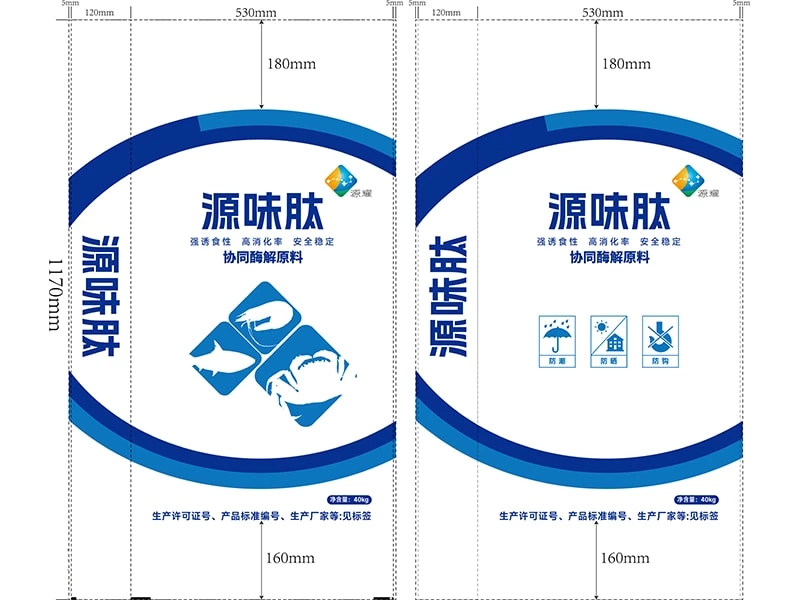

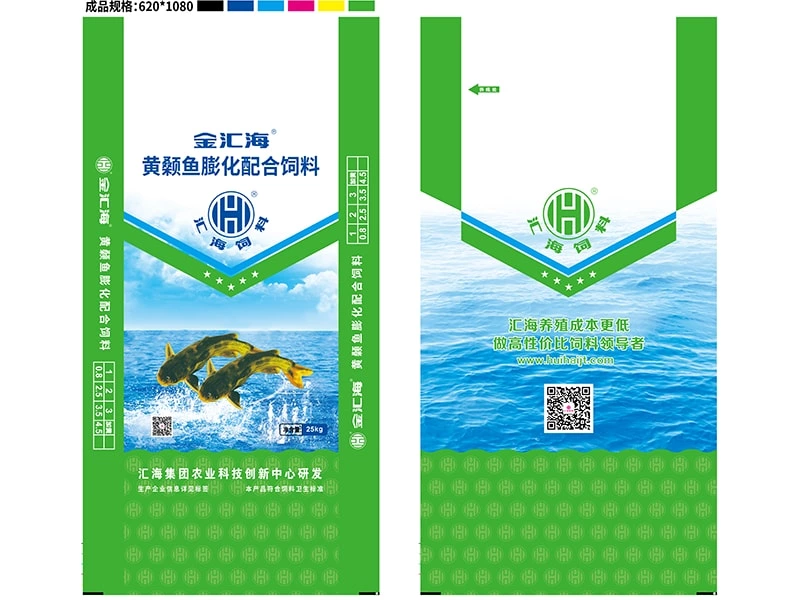

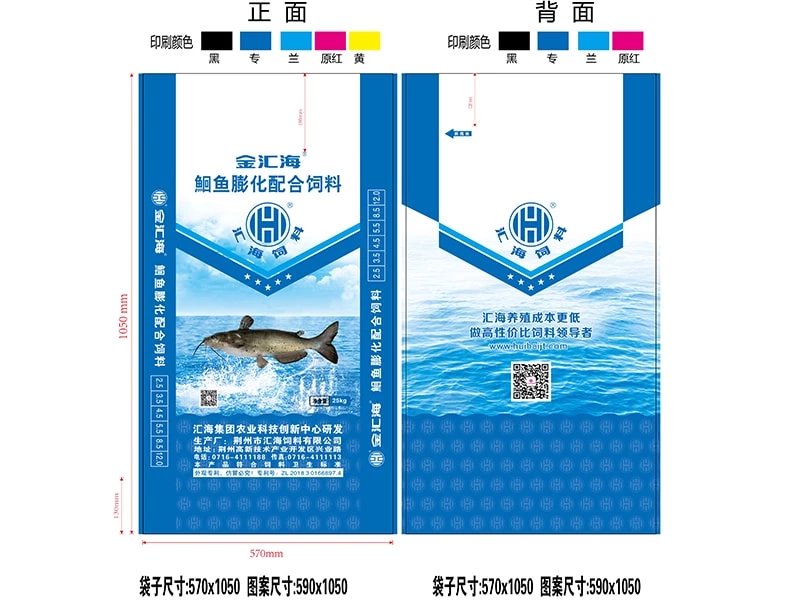

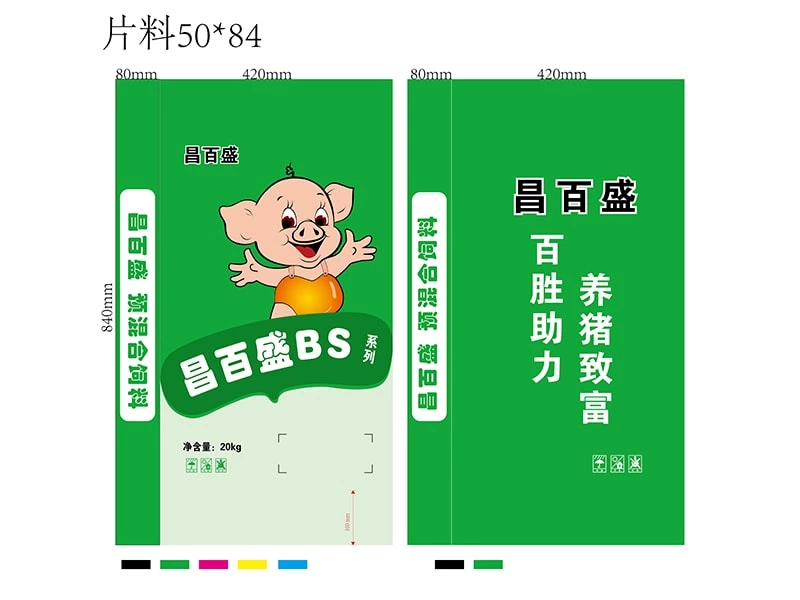

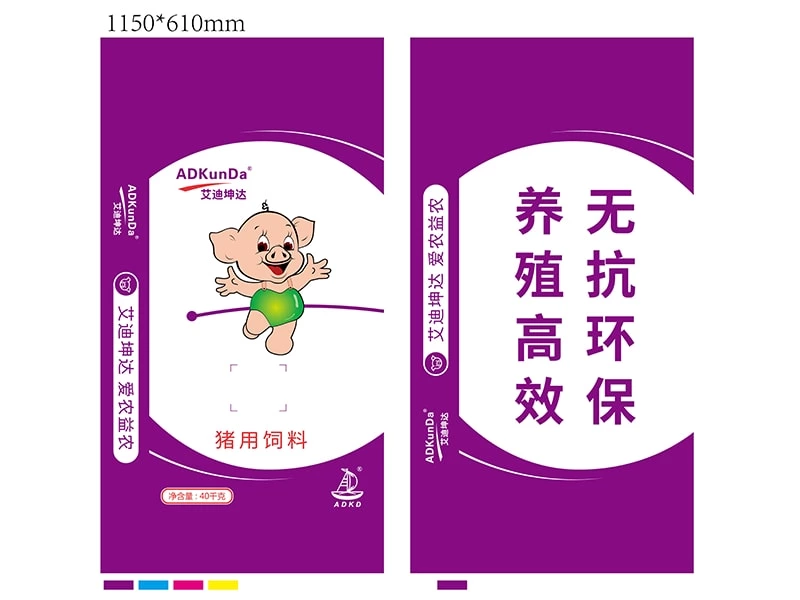

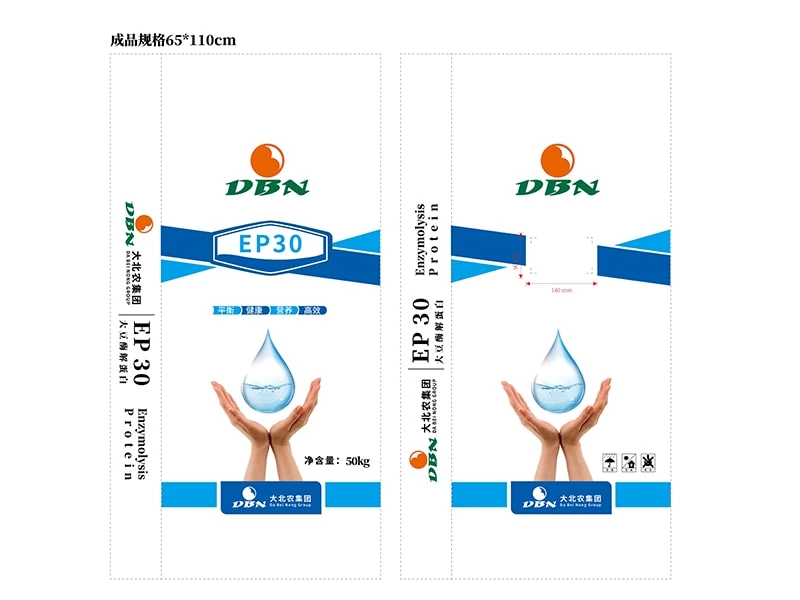

Our polyethylene bags can be fully customized to meet your specific requirements. Options include custom thickness, size, color, printing, resealable closures, gusset designs, and promotional branding elements. These tailored solutions not only protect your products but also enhance shelf appeal, improve operational efficiency, and elevate your brand’s visibility in the market.

Qiang Li

Purchasing Manager