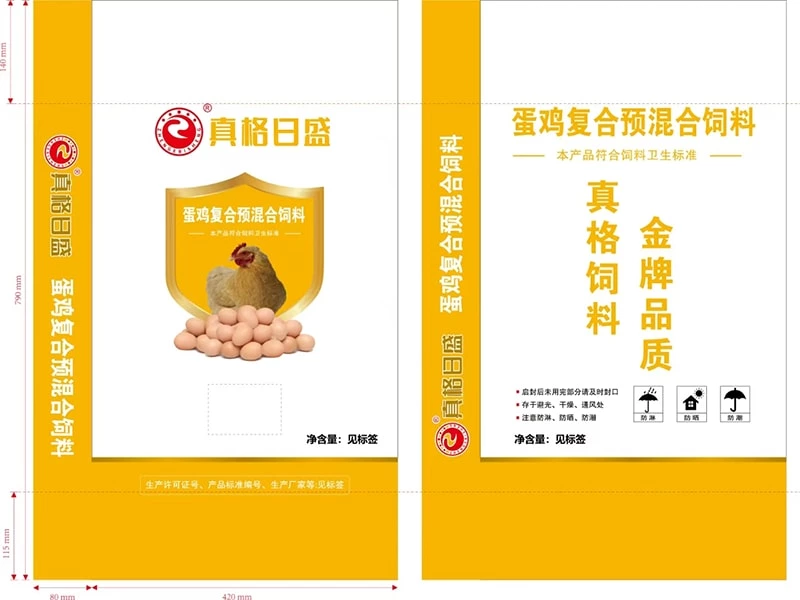

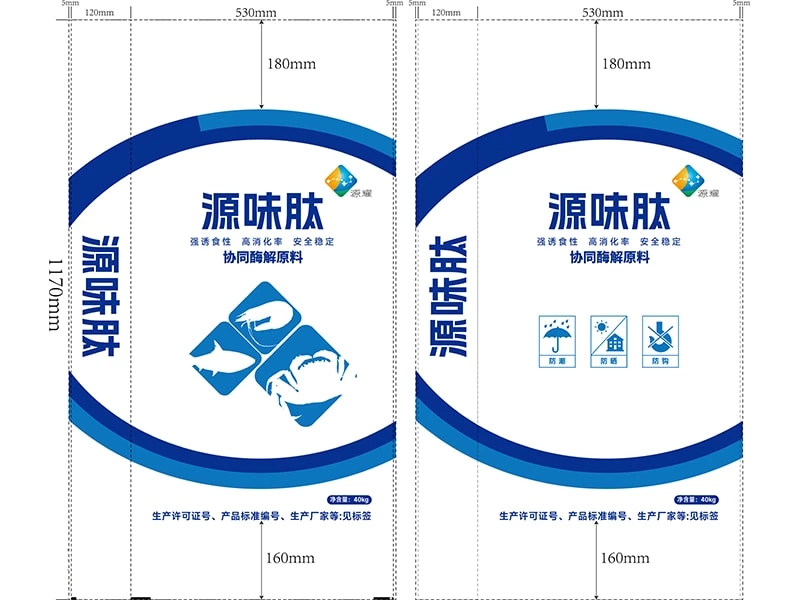

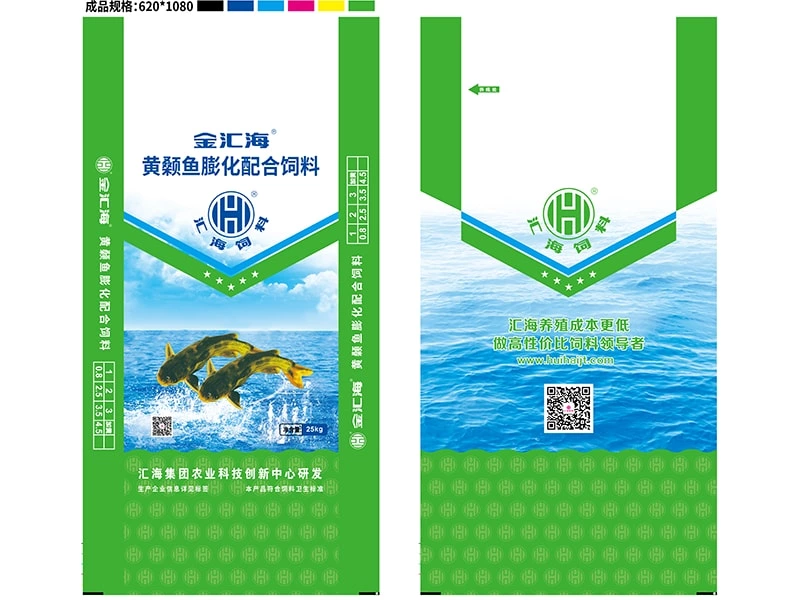

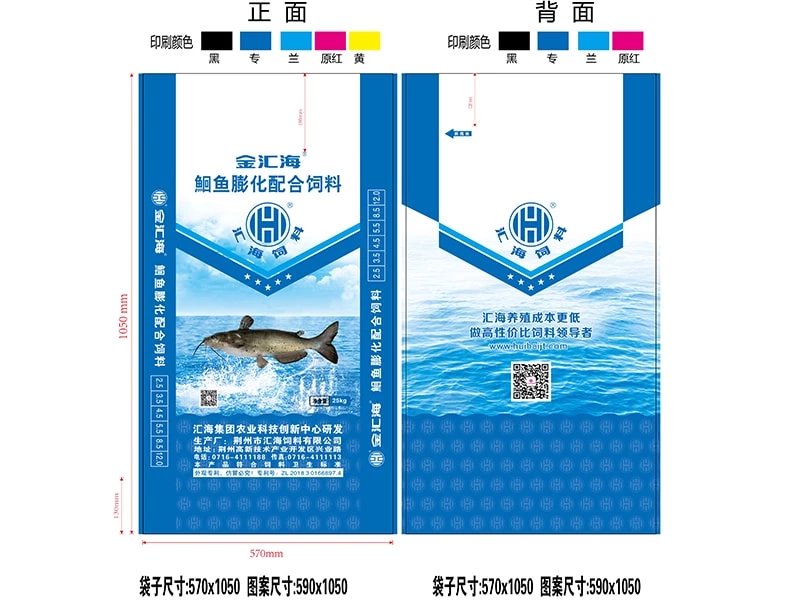

Industrial Woven Bags

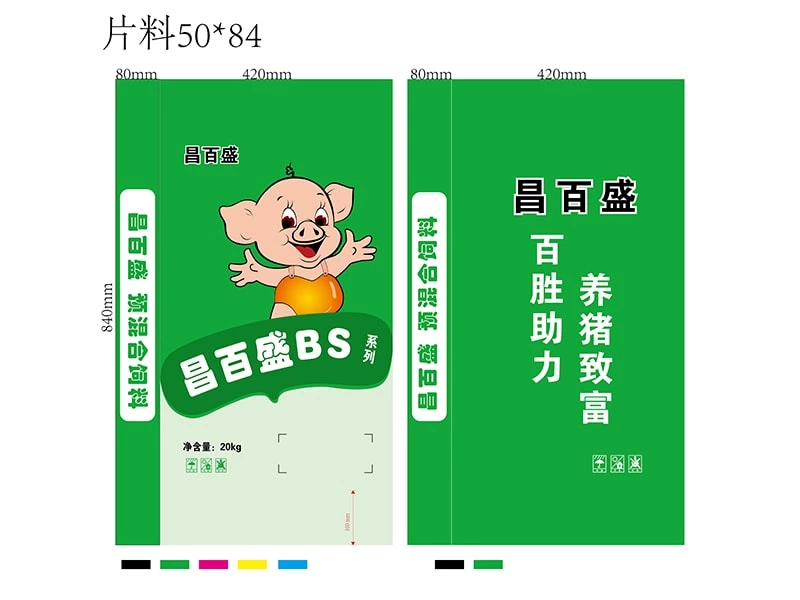

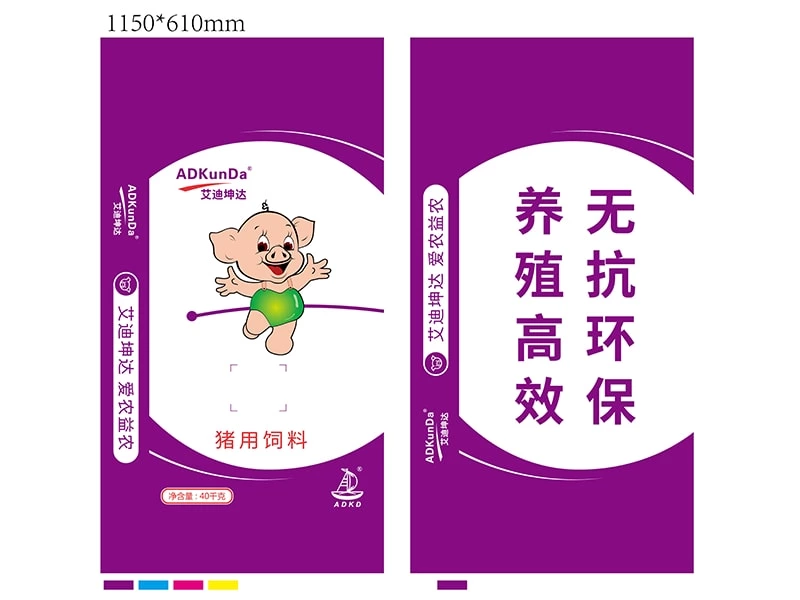

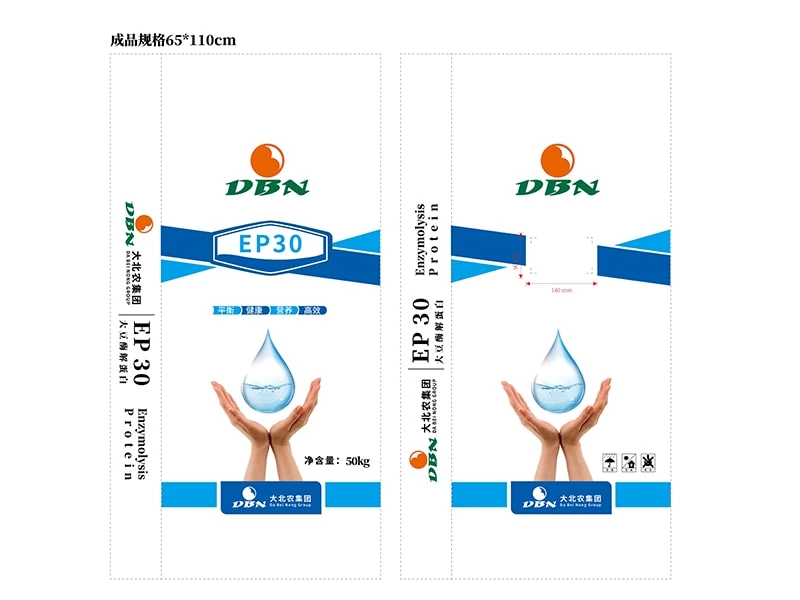

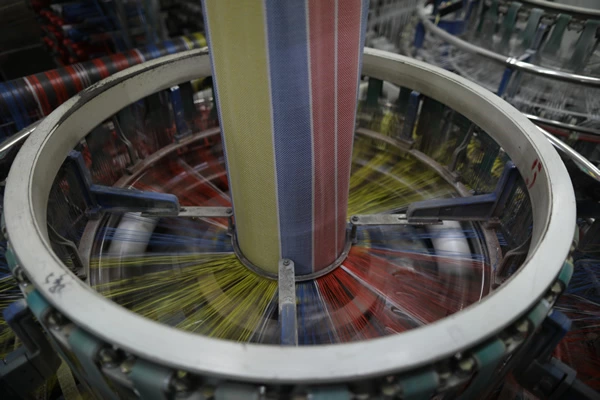

Our composite industrial woven bags are specially designed to meet the rigorous demands of bulk material packaging. Made with high-strength polypropylene (PP) and reinforced with laminated composite films, these bags offer superior protection, load capacity, and longevity across a wide range of industrial applications—from fertilizers and chemicals to building materials and animal feed.

We understand that industrial environments require tough, functional, and efficient packaging. That’s why our woven bags are available in various sizes, weights, and weave densities, with customizable features like UV protection, inner liners, anti-slip surfaces, and reinforced stitching. Whether you're handling sand, cement, resin, or metal parts, our bags deliver performance where it matters most.

To support sustainability and operational efficiency, we also offer recyclable and reusable options that reduce material waste while maintaining structural integrity. With tailored designs and robust construction, our industrial woven bags help streamline heavy-duty operations while protecting both product and workforce.

Qiang Li

Purchasing Manager